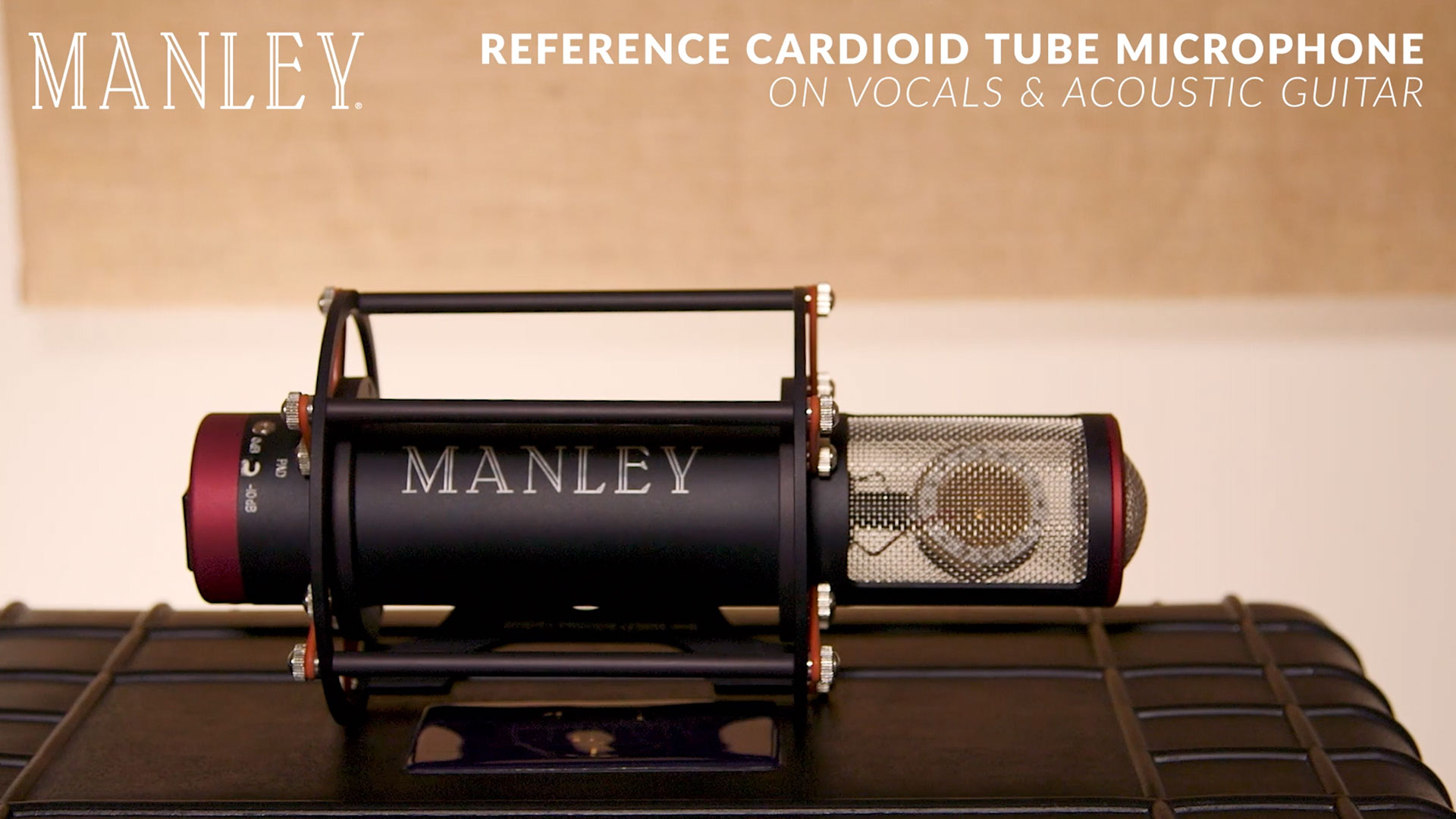

The world's most popular modern tube vocal mic.

The Manley Reference Cardioid Tube Microphone has that “finished” sound right out of the box, making it the favorite vocal mic of top producers and voiceover artists alike.This is modern pop music’s go-to mic: flattering, present, and larger-than-life. Some refer to the Manley Ref C as the “Just Add Talent” microphone.

WANT TO HEAR IT?

Compare all three Manley mics on the same sources and see which one is the best fit for YOU.“I use it for all my clients, and look where it got me.”

John Feldmann

(Good Charlotte, The Used, Mest, 5 Seconds of Summer, Blink-182)

DETAILS

The Reference Cardioid Microphone shares the same electronic attributes as the Gold Reference Series, but has a center-fixed cardioid-only capsule with a thicker gauge (6 micron) gold sputtered diaphragm. With the similar film thickness and construction, similar high frequency resonance (a little edge), similar proximity effect and pretty good immunity from pops and sibilance problems, our Reference Cardioid more closely recalls how many of the vintage European tube mics such as the beloved U47 sounded like when they were new. Its rich tonal balance and liquid character is consistently admired for instruments such as guitars, drum overheads, saxophone, and especially vocals. With your present mic, if you find yourself leaning on your compressors and boosting 5 or 10K to score a bit more testosterone, then the Reference Cardioid just might be the mic you’re looking for to cure what ails ya. If you seem to be constantly boosting 12-18K and trying to get a clean, intimate sound, then probably the Reference Gold would be the safest bet.

If you want to sound like God, then use the mic Don LaFontaine used! The Manley Reference Cardioid mic. And have a voice like his, too.

DRIVEN BY MANLEY POWER®

As of June 2020, the Reference Cardioid also utilizes our new MANLEY POWER® Switch-Mode Power Supply.

This new power supply is empirically quieter than the older PSUs. Sonically, we hear faster highs, generally more clarity, and ‘blacker blacks’ in the silence. The new power supply is also universal - accepting any voltage or frequency - so it works anywhere in the world without a voltage changeover switch or power transformer rewiring.

SPECIFICATIONS

All-Tube triode design utilizes 12AX7 or 7025EH (Previous versions used 12AT7 and 6072.)

-10 dB switchable pad

Frequency response: 10Hz-30KHz

Sensitivity: 17mV/Pa

Noise typically -120dB EIN

Max SPL: 150dB

Output Impedance: 250 Ohms

Weight: 2.25 lbs (mic)

Size: mic body 2" diameter x 9.7" long x 4.5" (mic suspension outside diameter)

Shipping weight: 15 lbs

POWER SUPPLY

As of 6/2020 SMPS Power Supply versions REFCARD7P####:

Universal MANLEY POWER™ Switch Mode Power Supply; works worldwide

Power Consumption: 8 Watts

Weight / Dims: 2.35 lbs / 5 x 3.3 x 9.3” (with handle)

Fuse: 250VAC 2A SLO BLO Ceramic - 5mm x 20mm

Input Voltage: 90VAC to 250VAC (Universal)

Mains Frequency: 50~60Hz

OLDER LINEAR POWER SUPPLY VERSION pre-2020:

Outboard Power Supply is factory set for 100V, 120V or 220-240VAC operation for original destination country's mains voltage.

Operating Mains Voltage changeable with power transformer re-wiring via internal jumpers and fuse value change.

Older units might have 120-220V Voltage changeover switch

Size: 5" x 9.3" x 3.3" (PSU including handle)

Weight: 2.6 lbs (PSU)

Mains Voltage Frequency: 50~60Hz

Mains Fuse Value: 250mA @ 100~120V; 125mA @ 220~240V operation

Mains Fuse Type: 5mm x 20mm SLO-BLO Glass or Ceramic

(older units used 1/4” x 1 1/4” size MDA or MDL type)Power Consumption: 70mA @ 120V = 8.4 Watts

REVIEWS

“I use it for all my clients, and look where it got me.”

– John Feldmann (Good Charlotte, The Used, Mest, 5 Seconds of Summer, Blink-182)

“The first thing that struck all of us when listening back in the control room was how massive the kick is. It was so punchy and booming that we had to make sure no other mics were on. Once soloed, we confirmed that this mic is a monster.”

– Rich Tozzoli, Pro Sound Network, August 2018

"The merit of the Manley Reference Cardioid is its extreme openness and high-end response. If you normally reach for the "air band" when EQing tracks, you probably won't have to with this mic."

– Ty Ford, Pro Audio Review, March 1998

“I read all the reviews on this mic and decided I have to try it out for myself and I was BLOWN AWAY. The hype is real and if you are looking for that polished pop vocal sound out of the box, I HIGHLY recommend the Manley Reference microphone.”

“I never thought I'd say this but I've fallen in love with my new Manley Mic!”

“I own several great mics for recording VO. My Manley Reference Cardioid is the flagship. It has a wonderfully silky, rich sound. I've owned several tube mics including some U47 clones, but the Manley is the one I kept. Deeply rich without sounding muddy. Nice airy high end without sounding sibilant. I highly recommend this mic!”

“Before I bought the mic, I was skeptical. I got the mic and everything changed. Now I'm a believer. It's now my favorite mic.”

“WoW!! The breakdown section came to life! It put the vocals up front and so in your face the way I love rock vocals. This mic required absolutely no EQ on the way in, just a touch of the Distressor to even out the vocal performance. The singer and band were so blown away, they have requested to retrack the rest of the song. It's that great! As I stated, this mic is a game changer!”

“I've recorded several albums of mine with many hit songs on about every mic. This is hands down the best mic I've used.”

– Reference Cardioid customer reviews (via Manley Dealer websites)

OWNER'S MANUAL

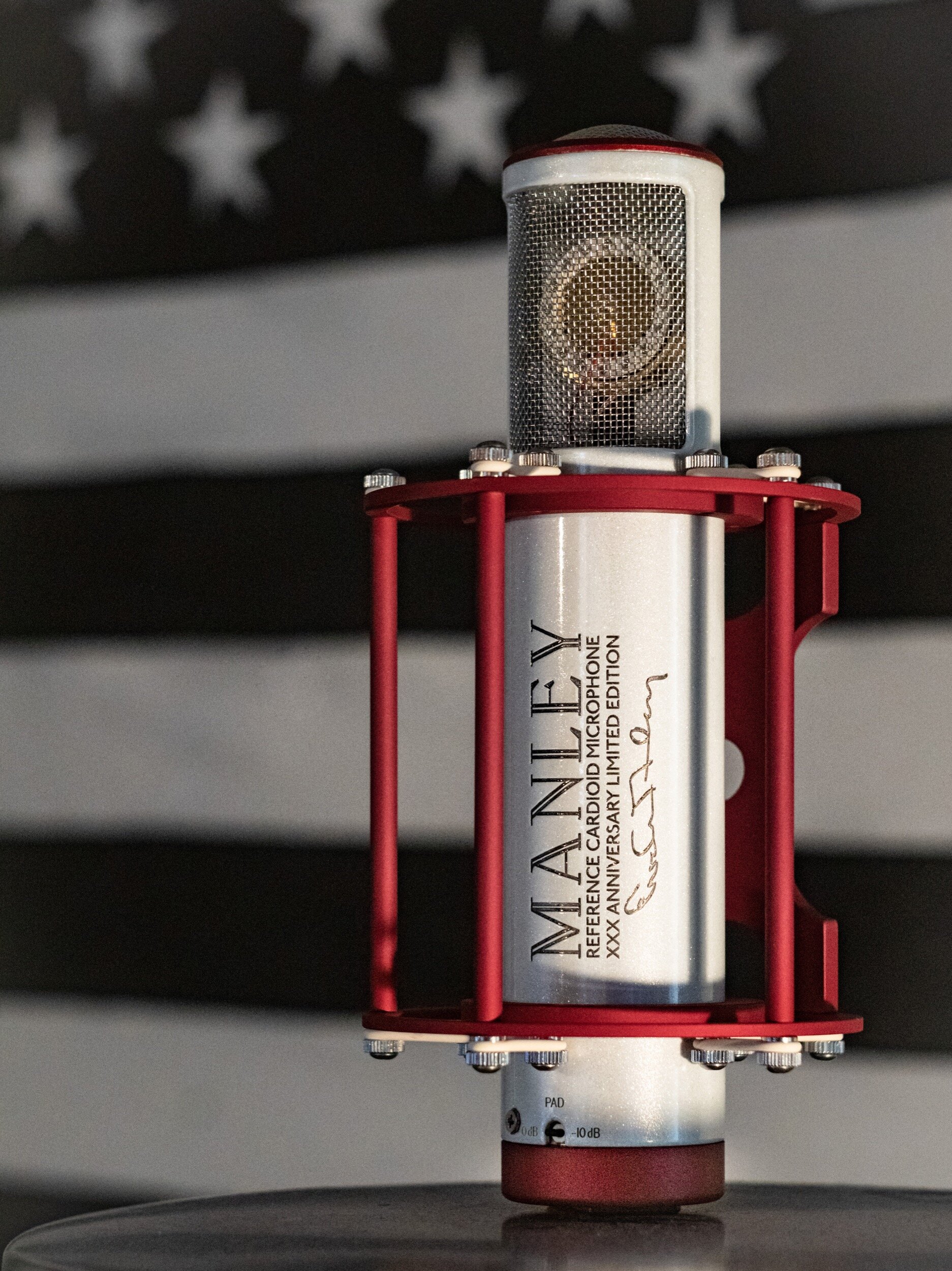

THE XXX ANNIVERSARY EDITION

In 2019, a limited run of Reference Cardioid mics were produced to commemorate the product’s 30th Anniversary. This run of 100 Reference Cardioids had custom pearlescent white and red cosmetics and a custom EveAnna Manley signature engraving, with a matching MANLEY POWER™ switch-mode power supply.

“…the appearance, performance, and application of the Reference Cardioid Limited Edition are very outstanding, and its sound quality is even more amazing. I am happy to call it the "Holy Grail" because it can almost satisfy all your wishes for sound.”

THE XX ANNIVERSARY EDITION

In 2011, a limited run of Reference Cardioid mics were produced to commemorate the product’s 20th Anniversary. This run of 50 Reference Cardioids had special black and blue cosmetics, with a custom EveAnna Manley signature engraving. They were bundled with special matching 15th Anniversary VOXBOX® channel strips, also limited to 50 units worldwide.

FREQUENTLY ASKED QUESTIONS

I just got one of your new microphones! What does that red button do on the power supply?

With MANLEY POWER® switch-mode microphone power supplies from mid-2020 onwards (see image on right), there is a red power switch / indicator on the rear side. With an IEC power cable connected, this switch’s LED will glow dimly to show that power is applied. When the switch is pressed to turn the unit on, it will glow bright red. So even if you see the switch glowing slightly, it does NOT mean your microphone is turned on – you still need to PRESS THE SWITCH to provide power to the mic.

Why should I order replacement microphone tubes from you?

The microphone grade tube is tested at the factory for lowest noise, using a test fixture we have built that duplicates the Manley microphone circuit. To the best of our knowledge, there are no other tube vendors that have this purpose-built tester. This testing yields very few tubes suitable for use in the microphones.

Tube quality, especially noise characteristics, varies over time and batch-to-batch. At any particular point in time, we may be using a different tube than what is listed. There is nothing "special" about a Sovtek or Ruby, or anything else we use; what is special is the characteristics we grade and select for including the low noise requirement, and the testing required to insure this.

I have a really old mic from the 1990’s that uses the 6072. Can I install a 12AX7 instead?

Sure you can, but you’ll need to make a couple of modifications.

Anode Resistor #1 change from 26K7 Ohms to 56K2 Ohms 1/2W Metal Film.

Anode Resistor #2 change from 100K Ohms to 221K Ohms 1/2W Metal Film.

Feedback resistor change from 681 Ohms to 562 Ohms 1/4W Metal Film.

Install network across tertiary feedback winding: 0.1uF 63V in series with 680 Ohms 1/2W Metal Film.

Install low noise 12AX7 or 5751 in place of 6072 or 12AY7.

Will the heat from the tube damage the capsule if I use the microphone upright?

Not at all. Our microphones can be used in any position, any orientation.

How to change the O-RINGS:

The mic suspension is held onto the mic by a set of red silicone o-rings connecting FIVE pillars surrounding the mic, one set on the top and the other on the bottom of the mic. There are two sets of stainless steel screws and spacer nuts that hold the silicone o-rings onto these points and all you do is loop the o-rings onto these posts inner and outer. You can double up the o-rings for extra security and put two of 'em on each point and order two sets (20 total) if you'd like to.

If you needs to order more o-rings, you can order a set of them from our parts store, www.tubesrule.com. They are RED SILICONE #114 O-RING's.

How to change a TUBE:

Here is a video that explains the general concept for the Manley Reference Mono microphones. Read on for more details: Disconnect the power cable at the mic. Do not remove the mic suspension. You never need to. Remove the three phillips screws at the base (red part) of the mic that hold the case on. Grasp the body of the mic with one hand, grasp the base with the other hand. Carefully pull at the base of the mic (sometimes a slight twist will help), and slide the base out of the body just enough to expose the tube. Grasp the tube while holding the tube socket, and wiggle and pull to remove it. Install a new tube and put the case back on.

BUZZ! My mic started buzzing! Those damn bees...

Here is a video that explains the general concept for the Manley Reference Mono microphones. Read on for more details: If you have a buzz through the audio coming from your microphone, that can be a ground continuity problem with the body of the mic making good ground connections. If the mic is buzzing when you are holding it only by its suspension or it is just setting on a table or on a mic stand and it stops when you touch the body and grill with your hand, then you need to check out all the grounding points on the mic.

For all of these tests, you never have to remove the suspension from the mic body. It can stay attached always.

The easiest first thing to check is the two (or three on older mics) flat head phillips screws that secure the body-tube of the mic to the base. With the mic on a towel on a table (so you don't scratch it) lying down sideways, using a #1 Phillips Screwdriver, loosen and remove the body-to-base screws. The Manley Reference Gold Mics do not require this procedure as gold is conductive. On the Reference Cardioid Mic, the black anodize under the flat head screws should be removed exposing the aluminum in the countersunk cone-shaped hole. If it's not showing silver in the countersink hole, use a 1/4" or 3/16" drill bit with your fingers to gently rotate the drill bit in the countersink to scrape away the anodize layer to expose the underlying aluminum.

Note that current production Manley mics use a stainless-steel 4-40 x 1/4" flathead screw in conjunction with an angled star washer to really dig in and make a good ground connection. Before that zinc-plated screws were used. If you happen to have black-oxide screws in your very old Manley mic, let's replace those with the stainless screw plus the internal tooth countersunk crinkle washer.

Now slide the body-tube of the mic away from the base just a little bit to expose the innards of the base of the microphone. Slide up and wiggle. (The base and guts of the mic are all contained by a sub-chassis.) Repeat the drill bit exercise with the two (or three in older Manley mics) that those body-to-base mounting screws go into so that the bottom of the angled flat head screw digs into the exposed aluminum of the threaded hole. Rotate the drill bit with your fingers to expose the aluminum and create a slight conical seat for the screw.

While you have the base exposed fully, in our older mics, you'll see some tapped holes around the circumference of the base that secure the XLR connector to the base. In really old Manley Gold mics, you'll also have a set-screw holding the 4-pin power connector to the base of the mic. It is important that these connectors are held tight and also that ground is carried to them by the grub screws. Using a 1/16" hex key, or Allen key, find those buried 4-40 x 1/4" grub screws in the base and back them out and re-tighten them to make the ground and physical connection integral again. (Lefty-Loosen, righty-tighty!) In very old mics, black-oxide coated grub screws were used. These days, we would use more conductive stainless steel set screws.

Our newest mic designs use a stock chassis mount XLR connector held by two screws to the bottom end of the microphone base. Let's make sure those 4-40 Flat Head Phillips screws are stainless-steel (or at least zinc-plated) and not black-oxide coated. Let's also remove one at a time and perform the drill bit clearing exercise under the screw head in the countersunk hole to make sure there is a good metal-to-metal contact for best ground connection.

Contact our Parts Department to get an up-to-date screw kit for your mic by filling in the Service & Parts Request Form.

At this point, after you put the mic back together and retest it, if the buzz is still there, with the mic on, see if touching the screen or top of the screen makes any buzz go away. Hold the XLR cable shell so you are making the ground path between the screen and the XLR cable metal shell. If the screen is loose, it will need to be expoxied back in place with silver conductive epoxy. If touching the case makes the buzz go away then we still have grounds not being made in the base of the mic so go back and repeat the base-screws grounding exercises.

If you have determined that it is not the screws, and it's not the screens, the next step would be to replace the vacuum tube with any good working 12AX7 or 12AT7 or 6072 you have kicking around to see if the tube is the problem. Sometimes tubes just do not rule...

Next step would be more advanced, checking the power supply volts, especially the heater regulator to make sure you have 12V coming off him... looking for a bad cap in the PSU that isn't doing his job of removing ripple, etc. If nothing you try works then we'll arrange an RA# for you to send it in. Give us a holler on the Manley Service Request Form if you need more help or a schematic.

I hear hissy spitting noises. Is my capsule bad?

Here is a video that explains the general concept for the Manley Reference Mono microphones. Read on for more details: When the mic capsule is near the end of its life, generally the mic will get noisy. If the vacuum tube gets noisy, generally it will be “white” noise (hiss), and will be constant in nature. Capsule noises can be intermittent and inconsistent. A bad capsule can be fine for a while, but may get noisy after brief usage, or with differences in temperature, humidity, etc. A quick test to determine if the capsule is at or nearing the end of its life is as follows: Connect the mic so it can be monitored with headphones. While listening, exhale gently directly into the windscreen at close range. You can say “HAAA” into the microphone. If there is a big “rushing” noise, whistling noises, or the sound completely fades away, this is a good indication that the mic capsule probably needs replacement, or at least a professional cleaning. Contact us using the Manley Service Request Form if you need us to look at this for you.

The capsule life is affected by age, temperature extremes, physical abuse, and high humidity. Mics in a high humidity environment or those that live close to the ocean generally have a shorter life than those kept in dry climates. Because the grill weave is very open to allow all of the high frequencies to get through, this also allows spit from a close vocalist to get to the capsule. It is recommended to use a Pop Screen / Filter to keep your capsule cleanest.

I can hear some hum coming from the power supply. I this normal?

One thing with the linear power supplies: the power transformer will be noisier at 50Hz elsewhere in the world than at 60Hz in the USA where we are. That is physics of power transformers.

PLACE your PSU box as far away the source that you are mic-ing as possible.

Make sure the surface you have the PSU setting on is not also acting as a resonant amplifier. We have seen wooden shelves for instance act as mechanical amplifiers for vibrating transformers.

Try placing the PSU on a concrete floor. Or a carpeted floor.

The PSU does not run hot and ventilation is not an issue so for now, if you have it placed far away, on a non-amplifying and non-resonant surface, and you are still picking it up with your microphone in your audio, place a blanket or pillow on it to reduce the radiated physical noise.

All of the sudden my mic lost all bass response. It’s almost like a High Pass Filter kicked in. What happened?

Here are three likely culprits:

No low end: could be bad capsule

No low end: could be open connection at output transformer

No low end: could be open 221K resistor

Fill out the Tech Support form here on this website and get in touch with our Service Team for further help.

It’s so weird. I am getting a staticy high frequency buzz sounding thing from the mic but it goes away when I put the 10dB Pad in.

This might be a problem with the output transformer if you see the part number 7227B on the mu metal can. So, let’s get that back to us so that we can replace the transformer and cure that high frequency oscillation for you.

Here’s one new on us! One customer in Los Angeles wrote to us with this cure: I have news that may be helpful for other clients- the noise was emitting from the Los Angeles power company’s electric meter located inside my commercial facility!

Amazingly, one sheet of aluminum foil over the city’s meter completely removes the noise being picked up by the Ref C. Easy fix- As such, I don’t feel a need to mod the mic. If you have any LA clients, particularly in a business location, with the noise, have them check the LADWP meter near them. Wonders never cease! Thank you and EveAnna!

Can I upgrade my older linear power supply to the new fancy MANLEY POWER® switchmode power supply?

Sorry to report but there are too many other changes between the linear PSU for the Manley RefCard and the MANLEY POWER® SMPS for the RefCard. It is not simply a matter of buying the other PSU. The whole guts of the mics are different, heaters run off 12v on the linear vs 6v on the SMPS, and some other circuit changes. The PCBs are different inside the mic as is the cabling and XLR jack: 6-pin for the linear versions and 7 pins for the SMPS versions. We are not offering trade-ins or upgrades or mods of any linear-to-SMPS versions of anything as the mods are too extensive.

Sorry bro!

Best course of action would be to sell the linear one and buy a new model SMPS version.

Serial numbers REFCARD7P#### indicate the new MANLEY POWER SMPS version.

Where is my mic's serial number?

The Manley Reference Microphone serial number is located on the inner face of the mic suspension plate flanking the hole where your mic stand attaches to the mic suspension.

I need a frequency response plot and a polar response chart!

In 30+ years of producing microphones we have never provided plots and charts as we do not have an anechoic chamber or empirically correct measuring space that would give you useful charts. So we don’t provide half-assed ones either. I have visited a microphone manufacturing facility in China and I witnessed a lady drawing a pretty curve by hand for each microphone they were packing up… yeah, really.

I need to buy a new cable but I don’t want to spend the shipping cost to buy your OEM cable and have to ship it to the UK when I can just buy one locally. Why should I buy your cable?

Without being able to clarify and qualify the specific cable in the UK you are contemplating purchasing, we cannot advise on any differences between what we know and what we do not know.

If you want a cable that is guaranteed to function properly, is wired correctly, provides best shielding practices, accommodates the audio signals and high current heater lines to specification, is built with longevity as a priority using premium connectors and wire made to our specifications, and is backed by our own warranty, then you should buy the Manley OEM cable. Otherwise, you are on your own to make the decision to use a non-OEM cable and put your microphone system out of warranty. Best luck with that.

How do I adjust the suspension? I want to slide it up just a little bit.

You will need an ALLEN KEY Imperial, 5/64th inch Allen/hex key used for the cap head Allen screws that secure each of the two inner rings to the mic's housing.

Look at the two inner rings and locate the recessed cap head Allen screw along the outer circumference.

Loosen the cap head Allen key screw on each of the inner suspension rings, which will loosen the two rings from the mic's housing.

Then slide the suspension rings into the new position you prefer. There are o-rings lining the inner circumference of each inner ring so they won’t scratch your mic housing. Usually you will want to rock or wiggle the inner ring into position. It is not advised to twist it into place. Once you have repositioned the inner rings to your liking, then you can retighten the Allen head screws on each of the two inner suspension rings.

My Manley Reference Microphone came with this neat metal swivel mount, but I'm not sure how to install and use it. Help?

Watch this video to learn all about it:

Oh and by the way, use a heavy mic stand and don’t knock it over! But if you do, the outer suspension rings are easy enough to replace.